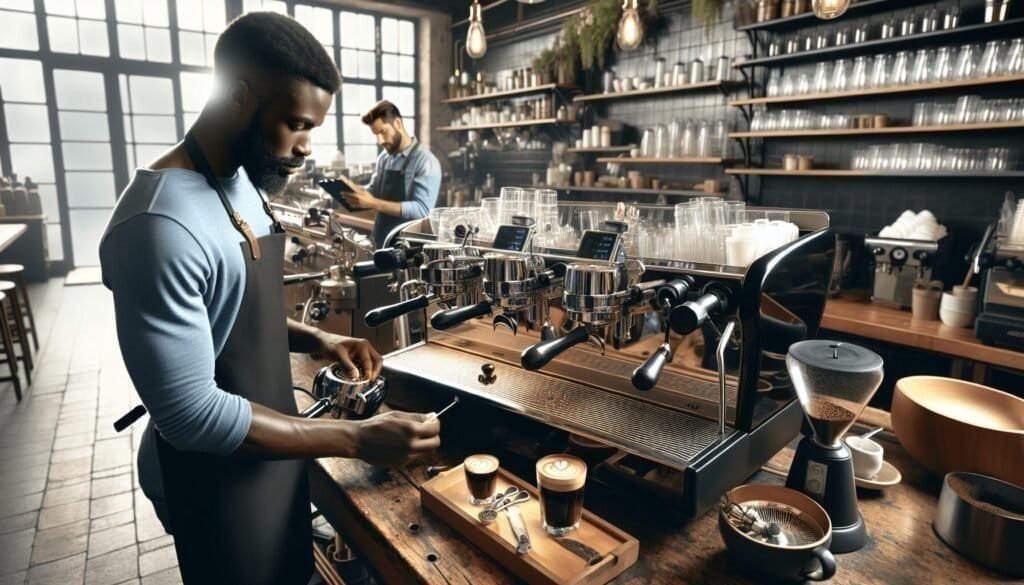

Maintaining advanced barista equipment is an art form that requires precision and creativity. From the sleek espresso machines to the intricate coffee grinders, this article will guide you through the best practices for ensuring the longevity and optimal performance of your prized equipment. Discover innovative techniques, expert tips, and creative solutions that will elevate your barista skills and keep your machines running like a well-oiled masterpiece. Say goodbye to downtime and hello to a flawlessly brewed cup of coffee every time.

Understanding your Barista Equipment

Knowing the parts and functions of your equipment

As a barista, it is crucial to have a comprehensive understanding of the different parts and functions of your barista equipment. By familiarizing yourself with the equipment, you will not only be able to operate it efficiently but also troubleshoot any issues that may arise during your shift. Take the time to study the user manual and identify the various components of your espresso machine, coffee grinder, and water filtration system. This knowledge will serve as a solid foundation for effective maintenance and troubleshooting in the long run.

Understanding the routine requirements of each component

Each component of your barista equipment requires routine care and attention to ensure optimal performance and longevity. For example, the group-head of your espresso machine should be regularly back-flushed to remove any coffee residues that could affect the taste of your espresso. Similarly, the hopper and burrs of your coffee grinder need to be cleaned regularly to prevent the build-up of old coffee grounds. By understanding and implementing these routine requirements, you can ensure that your equipment continues to produce high-quality beverages.

Recognizing the signs of potential problems

Being able to recognize the signs of potential problems is essential for maintaining and prolonging the life of your barista equipment. Keep an eye out for any unusual noises, leaks, or inconsistent performance. These could be indicators of underlying issues that require professional attention. By addressing these problems early on, you can prevent further damage and costly repairs down the line. Being proactive and observant will not only save you time and money but also ensure that your customers are consistently delighted with the beverages you serve.

Regular Cleaning and Sanitizing

Importance of daily cleaning

daily cleaning of your barista equipment is of utmost importance in maintaining hygiene and delivering the best possible tasting beverages. Leftover coffee residues can accumulate in various parts of your equipment, leading to off flavors and the potential growth of harmful bacteria. By incorporating a daily cleaning routine into your barista workflow, you can ensure that your equipment remains in pristine condition and continues to produce exceptional coffee. Regular cleaning will also mitigate the risk of cross-contamination and promote a safe working environment for you and your staff.

Proper methods of cleaning

When it comes to cleaning your barista equipment, there are specific methods that should be followed to ensure thoroughness and effectiveness. For example, the group-head of your espresso machine should be back-flushed using a specialized cleaning agent to remove any oils or residues. The hopper and burrs of your coffee grinder should be carefully brushed and wiped to eliminate coffee grounds. It is essential to understand and implement these proper cleaning methods to maintain the integrity of your equipment and guarantee the best possible tasting beverages.

Appropriate cleaning products

To ensure effective cleaning, it is crucial to use appropriate cleaning products for each component of your barista equipment. Different parts may require specific cleaning agents or tools to remove stubborn residues or mineral deposits. For example, descaling solutions may be necessary to prevent mineral build-up in your espresso machine. It is essential to consult the manufacturer’s recommendations and guidelines to identify the most suitable cleaning products for your specific equipment. Using the right cleaning products will yield optimal results and prolong the life of your barista equipment.

Sanitization requirements

In addition to regular cleaning, sanitization is also a critical aspect of barista equipment maintenance. Sanitizing surfaces that come in contact with coffee or milk will eliminate potentially harmful bacteria and ensure a safe working environment. This includes steam wands, milk frothers, and countertops. It is important to follow proper sanitization procedures and use approved sanitizing agents to guarantee effective sanitization. By incorporating sanitization into your daily cleaning routine, you can create a hygienic environment and provide your customers with beverages that have been prepared with the utmost care.

Preventive Maintenance

Establishing a regular maintenance schedule

Preventive maintenance is essential for the longevity and reliability of your barista equipment. By establishing a regular maintenance schedule, you can proactively address any potential issues and keep your equipment in optimal condition. This schedule should include tasks such as cleaning, calibration, and inspection of various components. By adhering to the maintenance schedule, you can prevent unexpected breakdowns and keep your barista equipment operating at its best.

Professional check-ups and servicing

While regular maintenance can be performed by the barista, it is also important to schedule professional check-ups and servicing for your barista equipment. Trained professionals have the expertise and knowledge to detect any underlying issues that may not be apparent to the untrained eye. They can conduct thorough inspections and make necessary adjustments or repairs to ensure the continued functionality of your equipment. By entrusting professionals with the servicing of your equipment, you can have peace of mind knowing that it is in capable hands.

Replacing worn parts before they cause damage

As with any piece of machinery, parts of your barista equipment will wear out over time. It is essential to identify and replace these worn parts before they cause further damage to your equipment. regular inspection and monitoring will allow you to identify any signs of wear or deterioration. Whether it’s replacing gaskets, seals, or even the burrs of your coffee grinder, addressing these issues promptly will help maintain the integrity and performance of your equipment, preventing costly breakdowns and prolonging its lifespan.

Proper Use and Handling of Equipment

Training staff on correct usage of machinery

proper use and handling of barista equipment are not only essential for its performance but also for the safety of your staff. It is crucial to provide comprehensive training on the correct usage of all equipment to your barista staff. This training should encompass everything from the basics of operating the espresso machine and coffee grinder to specific handling procedures for steam wands and milk frothers. By ensuring that your staff is well-versed in the proper use of the equipment, you can minimize user errors and maximize the longevity of your barista equipment.

Avoiding misuse and handling errors to prevent damage

Misuse and handling errors can lead to significant damage to your barista equipment. It is essential to educate your staff on the potential risks and consequences of mishandling the equipment. For example, forcefully packing espresso grounds into the filter basket or using improper cleaning tools can cause damage to the group-head and portafilter of the espresso machine. By emphasizing the importance of proper handling techniques and providing ongoing training and reminders, you can prevent unnecessary damage and ensure the longevity of your equipment.

Importance of proper shut-down and start-up procedures

Proper shut-down and start-up procedures are often overlooked but are vital for the maintenance and performance of barista equipment. When closing up shop for the day, it is crucial to follow the manufacturer’s guidelines for shutting down and cleaning your equipment. This includes properly flushing and draining the espresso machine and emptying and cleaning the coffee grinder. Similarly, when starting your day, it is important to follow the recommended start-up procedures to minimize the risk of damage and ensure optimal performance. By instilling the importance of these procedures in your barista staff, you can prevent unnecessary wear and tear on your equipment and maintain its reliability.

Espresso Machine Maintenance

Back-flushing the group-head

back-flushing the group-head is a crucial maintenance task for espresso machines. Over time, coffee oils and residues can accumulate in the group-head, affecting the flavor of your espresso and potentially causing blockages or other issues. Back-flushing involves the use of a specialized cleaning agent and is typically performed at the end of each day. By running the back-flush program on your espresso machine, you can effectively remove these residues and ensure the continued quality of your espresso.

Descaling to prevent mineral build-up

Mineral build-up can be a common issue in areas with hard water. Scale deposits can hinder the performance of your espresso machine and lead to clogged pipes or other malfunctions. Descaling involves the use of a descaling solution that breaks down and removes these mineral deposits. The frequency of descaling will depend on the water hardness and usage of your machine. It is important to consult the manufacturer’s recommendations and conduct regular descaling to prevent mineral build-up and maintain the efficiency of your espresso machine.

Periodic changing of gaskets and seals

Gaskets and seals play a critical role in maintaining the integrity of your espresso machine. Over time, they can deteriorate or become worn, leading to leaks or inconsistent performance. It is important to periodically inspect and replace these gaskets and seals to prevent further damage to your machine. Regularly changing gaskets and seals will ensure a proper seal and prevent the loss of pressure or leakage, ultimately preserving the functionality of your espresso machine.

Coffee Grinder Maintenance

Regular cleaning of the hopper and burrs

The hopper and burrs of your coffee grinder require regular cleaning to remove any coffee grounds or oils that can affect the taste of your coffee. It is recommended to clean the hopper and burrs after each use or at the end of each day. This can be done by removing the hopper and brushing out any remaining grounds or residues. Pay close attention to the burrs, ensuring they are free from any blockages or build-up. By incorporating regular cleaning into your routine, you can keep your coffee grinder in optimal condition and ensure the consistency of your coffee grounds.

Checking and replacing the burrs

The burrs in your coffee grinder are responsible for grinding the coffee beans to the desired consistency. Over time, burrs can become dull or chipped, affecting the quality of your grounds. It is important to regularly inspect the burrs for any signs of wear and replace them as necessary. The frequency of burr replacement will depend on the usage and type of coffee being ground. By ensuring that your burrs are sharp and intact, you can maintain the performance and consistency of your coffee grinder.

Alignment and calibration of grinder

The alignment and calibration of your coffee grinder are essential for achieving consistent and accurate grind settings. With prolonged use, the burrs may become misaligned, leading to uneven grind sizes and inconsistent extraction. It is important to periodically check the alignment of the burrs and make any necessary adjustments. Calibration may also be required to ensure accurate grind settings for different brewing methods. By paying attention to the alignment and calibration of your coffee grinder, you can achieve optimal extraction and deliver exceptional coffee to your customers.

Water Filtration System Maintenance

Checking and changing filters regularly

The water filtration system is an integral part of your barista equipment, as it ensures the quality and taste of your beverages. Regularly checking and changing the filters is essential to maintain the efficacy of the system. Filters can become clogged with impurities and minerals over time, leading to decreased water quality and potential damage to your equipment. It is important to follow the manufacturer’s recommendations for filter replacement intervals and conduct regular checks to ensure the water filtration system is operating optimally.

Monitoring water hardness and adjusting accordingly

Water hardness can vary depending on the location, and it can significantly impact the performance of your barista equipment. Hard water can lead to mineral build-up and affect the taste of your beverages. It is important to monitor the water hardness regularly using test strips or a water hardness meter. Based on the results, adjustments can be made to the water filtration system to optimize water quality and prevent any adverse effects on your equipment. By maintaining the appropriate water hardness level, you can ensure consistent taste and protect your barista equipment from unwanted mineral deposits.

Scheduled maintenance from professionals for technical issues

While regular maintenance of your water filtration system can be performed in-house, certain technical issues may require the expertise of professionals. These issues can include leaks, malfunctioning valves, or problems with the filtration process. It is important to establish a relationship with professionals who specialize in the maintenance of water filtration systems. Regularly scheduled maintenance visits can help identify any potential problems and ensure that your system is functioning optimally. By relying on the expertise of these professionals, you can have peace of mind regarding the water quality and performance of your barista equipment.

Diligent Record Keeping

Logging maintenance and servicing activities

Maintaining accurate records of maintenance and servicing activities is essential for effective barista equipment maintenance. By logging the dates and details of routine maintenance, cleaning, and service visits, you can keep track of the history and condition of your equipment. This record-keeping will allow you to identify any patterns or recurring issues and make informed decisions regarding future maintenance and replacement. Additionally, having detailed records will also assist in warranty claims and provide proof of regular maintenance, which may be required by equipment manufacturers.

Maintaining records of repairs and replacements

In addition to recording routine maintenance and servicing, it is important to maintain records of any repairs or replacements that have been performed on your barista equipment. This includes details such as the date of the repair, the specific part that was replaced, and the reason for the repair. By keeping these records, you can track the performance of your equipment and identify any recurring issues that may require attention. These records will also provide valuable information when it comes to budgeting for future repairs or replacement of equipment.

Using records to predict upcoming maintenance needs

A comprehensive record-keeping system for your barista equipment maintenance can also be used to predict upcoming maintenance needs. By analyzing past data and identifying trends, you can anticipate when certain components may need to be replaced or when routine maintenance should be scheduled. This proactive approach to equipment maintenance will help minimize downtime and prevent unexpected breakdowns. By utilizing the information captured in your records, you can stay one step ahead and ensure the continued reliability and performance of your barista equipment.

Handling Unexpected Breakdowns

Basic troubleshooting guide

No matter how diligent you are in maintaining your barista equipment, unexpected breakdowns can still occur. In such situations, having a basic troubleshooting guide can help you identify and resolve minor issues. The troubleshooting guide should include common problems, their potential causes, and the corresponding steps to take to rectify the issue. By equipping yourself and your staff with this knowledge, you can quickly address small problems and avoid unnecessary downtime. However, it is important to note that for more complex issues, it is best to seek professional assistance.

When to call a professional

While basic troubleshooting can help resolve minor issues, there are instances when it is necessary to call a professional for assistance. Complex problems involving electrical components or significant malfunctions should be handled by trained professionals. Attempting to fix these issues without the proper knowledge and experience can potentially worsen the problem or pose a safety risk. It is crucial to have a reliable and trusted professional on hand to call for assistance when needed. By promptly involving professionals, you can ensure the proper repair of your equipment and minimize any disruptions to your barista operations.

Precautions to prevent further damage

When faced with an unexpected breakdown, it is important to take precautions to prevent further damage to your barista equipment. This can include actions such as disconnecting the equipment from the power source and shutting off the water supply. These precautions will help minimize the risk of electrical damage or flooding. It is also important to clearly communicate the issue to your staff and ensure they are aware of any temporary adjustments or workarounds that need to be implemented to maintain service. By taking these precautions, you can mitigate the impact of the breakdown and expedite the repair process.

Adaptive Maintenance for High-Efficiency

Staying informed about latest equipment trends and upgrades

To ensure high efficiency in your barista operations, it is important to stay informed about the latest equipment trends and upgrades. The coffee industry is constantly evolving, and new technologies and features are regularly introduced to improve the barista experience. By keeping abreast of these developments, you can identify opportunities for improvement and explore equipment upgrades that can enhance your workflow and efficiency. Staying informed can also give you a competitive edge in delivering exceptional beverages and staying ahead of customer preferences and expectations.

Adapting workflow for increased efficiency

Adapting your workflow to maximize efficiency is an ongoing process that requires continuous evaluation and adjustment. By carefully analyzing your current workflow, you can identify areas of improvement and implement changes to streamline operations. This can include rearranging equipment for better ergonomics, optimizing the placement of supplies and tools, or reorganizing workstations to minimize unnecessary movement. By continually seeking ways to improve workflow efficiency, you can optimize your barista operations and provide exceptional service to your customers.

Exploring and incorporating technological advancements

Technological advancements in the coffee industry can greatly enhance the efficiency and performance of your barista equipment. From automated milk frothers to advanced espresso machine controls, there are numerous innovations available that can revolutionize your barista operations. It is important to explore these advancements and evaluate their potential benefits for your specific needs and workflow. Embracing new technologies can streamline your operations, improve consistency, and elevate the overall barista experience. By incorporating these advancements, you can stay at the forefront of the industry and provide an exceptional coffee experience to your valued customers.

In conclusion, advanced barista equipment requires comprehensive maintenance to ensure optimal performance and longevity. Understanding the parts and functions of your equipment, following proper cleaning and sanitization procedures, establishing a regular maintenance schedule, training your staff on proper usage, and staying on top of necessary repairs and replacements are all essential aspects of effective equipment maintenance. Additionally, recognizing the signs of potential problems, handling unexpected breakdowns with precautions, and staying informed about the latest advancements in barista equipment are key factors in maintaining high-efficiency operations. By implementing these best practices, you can prolong the life of your barista equipment, deliver exceptional beverages, and provide a remarkable coffee experience to your customers.